赞

赞

的个人主页 http://shi.cqjj8.com/yanxin/zh_CN/index.htm

学科领域:长时间尺度原子模拟及多尺度模拟材料微观结构设计及成型工艺设计

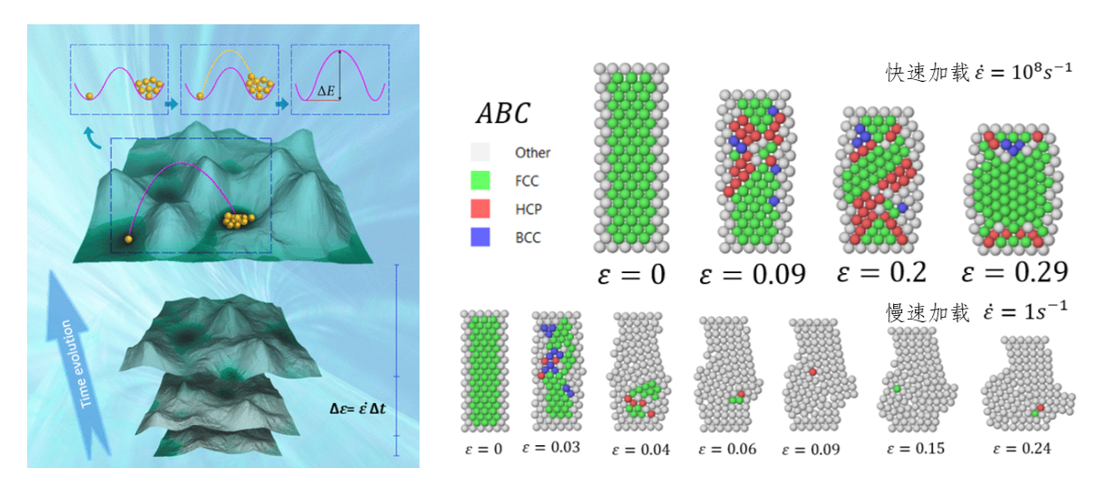

一、长时间尺度原子模拟

针对传统分子动力学模拟的时间短, 难以分析长时间尺度物理现象(如扩散、塑性变形等)的问题,开展基于势能面扫描的长时间尺度原子模拟算法研究,实现原子尺度长时模拟和低速加载;根据实际物理问题,基于LMAMPS框架开发包含简并态搜索、驱动函数自学习、恒定应变率加载等不同功能的计算模块。

代表性文章:

[1]Xin Yan and Pradeep Sharma, "Time-scaling in atomistics and the rate-dependent mechanical behavior of nanostructures", Nano Letters, 16.6 (2016): 3487-3492.(![]() pdf)

pdf)

[2] Wenqing Zhu, Yao Deng, Junjie Liu, Xin Yan* and Xiaoding Wei*, "independent transition of the relaxation dynamics in metallic glasses", Modeling and Simulation in Materials Science and Engineering 32 (2024):035026 (![]() pdf)

pdf)

[3] Jiao Wen, Jingyong Sun*, Boxuan Du, Yu Chen, and Xin Yan*,"The interfacial stability of single crystal superalloy affected by the phase structure of the Ni-Al coating", Scripta Materialia,227 (2023): 115297(![]() pdf)

pdf)

[4]Xin Yan, Afif Gouissem, Pradeep R. Guduru and Pradeep Sharma*, "Elucidating the atomistic mechanisms underpinning plasticity in Li-Si nano-structures", Physical Review Materials, 1(2017): 055401 (![]() pdf)

pdf)

[5]Faezeh Darbaniyan, Xin Yan*and Pradeep Sharma*,"an atomistic perspective on the effect of strain rate and lithium fraction on the mechanical behavior of silicon electrodes", Journal of Applied Mechanics,87(2020): 031011 (![]() pdf)

pdf)

[6]Xin Yan, Penghui Cao, Weiwei Tao, Pradeep Sharma, and Harold S. Park, "Atomistic modeling at experimental strain rates and time scales", Journal of Physics D:Applied Physics, 49 (2016): 493002 (![]() pdf)

pdf)

[7] Yan Xin, Afif Gouissem, and Pradeep Sharma. "Atomistic insights into Li-ion diffusion in amorphous silicon." Mechanics of Materials 91 (2015): 306-312.(![]() pdf)

pdf)

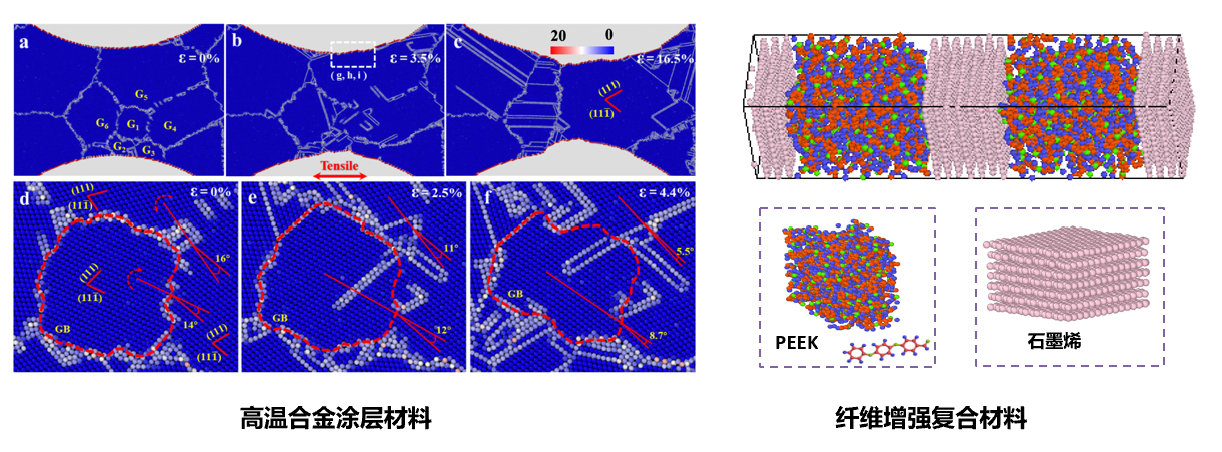

二、材料微观力热机理

针对构件成型过程异质材料界面的形成及演化微观机理不清问题,开展材料微观力热机理研究,研究内容包括高温合金涂层界面微观力热性能分析和纤维增强复合材料界面微观力热性能分析。

代表性文章:

[1] Xin Yan*, Md Sojib Kaisarb, Rubayet Hassanb, Fatemeh Ahmadpoor*. "Buckling and imperfection sensitivity of fluctuating one and two dimensional nanostructures." Journal of the Mechanics and Physics of Solids 206 (2026): 106342.(![]() pdf)

pdf)

[2] Hassan, Rubayet, Mingze Cai, Anh Vo, Samaneh Farokhirad, Xin Yan* and Fatemeh Ahmadpoor*. "Entropic pressure on a confined biological vesicle with surface tension." Journal of the Mechanics and Physics of Solids (2025): 106193. (![]() pdf )

pdf )

[3]Yizhong Guo, Jiao Teng, Guo Yang, Ang Li, Yao Deng, Chengpeng Yang, Lihua Wang*, Xin Yan*, Ze Zhang, Xiaoyan Li, En Ma, and Xiaodong Han*,"In situ observation of atomic-scale processes accomplishing grain rotation at mixed grain boundaries ", Acta Materialia 241 (2022): 118386 (![]() pdf)

pdf)

[4] Siqin Liu, Yanan Zhang, Xin Yan*, Wuxiang Zhang, and Xilun Ding. "Interfacial effects on thermal conductive properties in PEEK composites." International Journal of Heat and Mass Transfer 246 (2025): 127037(![]() pdf)

pdf)

[5]Zhanxin Wang, Yizhong Guo, Yan Ma, Chengpeng Yang, Yadi Zhai*, Xin Yan*, Lihua Wang*, and Xiaodong Han, "Effects of twin thicknesses on incoherent twin-boundary structures in face-centered cubic metals", Science China Materials 66.11(2023):4342-4348 (![]() pdf)

pdf)

[6]Libo Fu, Deli Kong, Chengpeng Yang, Jiao Teng, Yan Lu, Yizhong Guo, Guo Yang, Xin Yan*, Pan Liu, Mingwei Chen, Ze Zhang, Lihua Wang* and Xiaodong Han*, “Ultra-high strength yet superplasticity in a hetero-grain-sized nanocrystalline Au nanowire", Journal of Materials Science & Technology,101 (2022): 95-106 (![]() pdf)

pdf)

[7] Yu Chen, Shengjie Tang, and Xin Yan* "Manipulating the crack path through the surface functional groups of MXenes", Nanoscale,14(2022):144169 (![]() pdf)

pdf)

[8] Zhang, Qi, Yu Chen, Yifan Zhang, Jingyong Sun, Mingjun Hu, Xin Yan*, Kaijun Yuan*, Xueming Yang, and Jiebo Li*. "Surface Oxidation Modulates the Interfacial and Lateral Thermal Migration of MXene (Ti3C2T x) Flakes." The Journal of Physical Chemistry Letters 11, no. 22 (2020): 9521-9527.(![]() pdf)

pdf)

三、复合材料跨尺度模拟

针对连续纤维增强3D打印微观工艺机理不明晰问题,开展原子模拟-相场耦合连续纤维增强复合材料成型工艺机理研究,构建微-介观工艺状态数据库,提出数据模型辅助复杂力热载荷条件下组合缺陷协同抑制策略。

代表性文章:

[1] Wang, Shenru, Xin Yan*, Baoning Chang, Siqin Liu, Lihua Shao, Wuxiang Zhang*, Yingdan Zhu*, and Xilun Ding, "Atomistic Modeling of the Effect of Temperature on Interfacial Properties of 3D-Printed Continuous Carbon Fiber-Reinforced Polyamide 6 Composite: From Processing to Loading", ACS Applied Materials & Interfaces, 15, no. 48 (2023): 56454-56463 (![]() pdf)

pdf)

[2]Wang, Shenru, Xin Yan*, Baoning Chang, Jiae Zhang, Siqin Liu, Fei Liu, Junfan Shang,Li-Hua Shao, Sha Yin, Wuxiang Zhang*,Yingdan Zhu*,Xilun Ding, "A review on modeling strategies in understanding the process mechanism of 3D printed continuous fiber-reinforced thermoplastic composites." Journal of Manufacturing Processes 145 (2025): 46-70 (![]() pdf)

pdf)

[3]Huiyuan Wang#, Siqin Liu#, Xincheng Yin#, Mingming Huang, Yanzhe Fu, Xun Chen, Chao Wang,Jingyong Sun, Xin Yan∗, Jianmin Han∗, Jiping Yang, Zhijian Wang∗, Lizhen Wang, Yubo Fan∗ and Jiebo Li∗. "Polar-coordinate line-projection light-curing continuous 3D printing for tubular structures." International Journal of Extreme Manufacturing 6, no. 4 (2024): 045004(![]() pdf)

pdf)

[4]燕鑫, 王莘儒, 刘思琴, 等. 连续纤维增强热塑性复合材料构件增材制造工艺力学及机制的多尺度模拟研究进展[J]. 复合材料学报, 2024, 41(9): 4502-4517.(![]() pdf)

pdf)